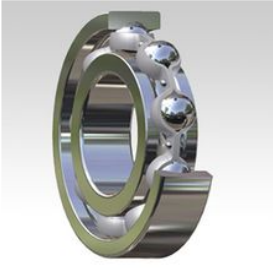

Deep groove ball bearing

Deep groove ball bearings are one of the most common types of rolling bearings. The basic structure includes an outer ring, an inner ring, a set of steel balls and a cage. Deep groove ball bearings have two types of single row and double row, and can be divided into two types of sealed and open structure. The open bearing has no sealing structure, and the sealed deep groove ball bearing is divided into dust seal and oil seal.

Deep groove ball bearings are the most common type of rolling bearings. The basic structure includes an outer ring, an inner ring, a set of steel balls and a cage. Deep groove ball bearings are divided into single row and double row two, the structure can also be divided into sealed and open two. The open bearing has no sealing structure, and the sealed deep groove ball bearing is divided into dust seal and oil seal. Dust seal cover is usually made of steel plate stamping, mainly used to prevent dust from entering the bearing raceway. The oil-proof seal is a contact type oil seal, which can effectively prevent the leakage of grease in the bearing.

Working principle

Deep groove ball bearings mainly bear radial loads, but also can bear both radial and axial loads. When only radial load is applied, the contact Angle is zero. When the deep groove ball bearing has a large radial clearance, it can bear a large axial load. The friction coefficient of deep groove ball bearings is very low, and the limit speed is also very high.

Bearing construction

Deep groove ball bearings are simple in structure, easy to achieve higher manufacturing accuracy compared with other types, easy to mass production, and low cost. In addition to the basic type, there are a variety of variant structures, such as deep groove ball bearings with dust cover, deep groove ball bearings with rubber seals, deep groove ball bearings with stop grooves, large load capacity deep groove ball bearings with ball notches and double row deep groove ball bearings.

Bearing type

Single row deep groove ball bearing

Single row deep groove ball bearing with dust cover

Single row deep groove ball bearing with dust cover and sealing ring

A single row deep groove ball bearing with a stop groove and a stop ring on the outer ring

Deep groove ball bearing with ball filling gap

Double row deep groove ball bearings

According to the size of the deep groove ball bearing can be divided into:

Miniature bearings: bearings with nominal outer diameter size range of 26mm or less.

Small bearings: bearings with nominal outer diameter size range of 28-55mm.

Small and medium-sized bearings: bearings with nominal outer diameter ranging from 60 to 115mm.

Medium and large bearings: bearings with nominal outer diameter ranging from 120-190mm.

Large bearings: bearings with nominal outer diameter ranging from 200-430mm.

Extra-large bearings: bearings with nominal outer diameter size range of more than 440mm.

Installation method

Press fit: When the inner ring of the bearing is closely matched with the shaft and the outer ring is loosely matched with the bearing seat hole, the bearing can be pressed on the shaft first by a press, and then the shaft and the bearing are loaded into the bearing seat hole together. An assembly sleeve made of a soft metal material (such as copper or mild steel) should be padded on the end face of the bearing inner ring during pressing. When the bearing outer ring is closely matched with the bearing seat hole and the inner ring is loosely matched with the shaft, the bearing can be pressed into the bearing seat hole first, and the outer diameter of the assembly sleeve should be slightly less than the diameter of the seat hole. If the bearing ring is a tight fit with the shaft and seat hole, it is necessary to press the shaft and seat hole at the same time, and the structure of the assembly sleeve should be able to press the end face of the bearing inner ring and the outer ring at the same time.

Heating fit: By heating the bearing or bearing seat, the use of thermal expansion to change the tight fit into a loose fit installation method. This method is suitable for bearing installation with large interference. Before hot loading, put the ring of the bearing or separable bearing into the oil tank and heat it evenly to 80-100℃, and then take it out of the oil and install it on the shaft as soon as possible. In order to prevent the inner ring end face and shaft shoulder from fitting tightly after cooling, the bearing can be axially tightened after cooling. When the bearing outer ring is closely matched with the bearing seat made of light metal, the hot loading method of heating the bearing seat can be used to avoid bruising the mating surface. When using the tank to heat the bearing, ensure that the grid is placed at a certain distance from the bottom of the tank, or the bearing is suspended with a hook to prevent impurities from entering the bearing or uneven heating. There must be a thermometer in the tank to strictly control the oil temperature not exceeding 100 ° C to prevent the tempering effect and reduce the hardness of the ring.

Bearing characteristic

Deep groove ball bearing is one of the most representative rolling bearings, widely used. Suitable for high and even extremely high speed operation, and very durable, no frequent maintenance. This kind of bearing has the advantages of small friction coefficient, high limit speed, simple structure, low manufacturing cost and easy to achieve high manufacturing accuracy. The size range and form are varied, used in precision instruments, low noise motors, automobiles, motorcycles and general machinery and other industries, is the most widely used class of bearings in the machinery industry. Mainly bear radial load, can also bear a certain amount of axial load.

Size range

Inner diameter range: 10mm ~ 1320mm

Outer diameter range: 30mm ~ 1600mm

Width size range: 9mm ~ 300mm

allowance

Standard deep groove ball bearings have common grades, all consistent with GB307.1.

play

Standard deep groove ball bearings have C2, standard (CN), C3, C4 and C5 internal clearance, all in line with GB4604.

cage

Deep groove ball bearings usually use steel plate pressed cages or brass solid cages. When the outer diameter is less than 400 mm, the steel plate stamping cage is used without a post code; When the outer diameter is greater than 400 mm, the multi-purpose brass solid cage does not add a rear code.

Apply

Deep groove ball bearings can be used in transmissions, instruments, motors, household appliances, internal combustion engines, traffic vehicles, agricultural machinery, construction machinery, construction machinery, roller skates, yo-yo balls and so on.

Matters needing attention

In the operation of deep groove ball bearings, if the bearing load is too small, it will cause sliding between the ball and the raceway, which will become the cause of abrasion. In particular, large deep groove ball bearings with large ball and cage weight have this tendency. It is expected that the load will be too small in use, and the relevant personnel should be contacted in time when selecting bearings!

Cause of corrosion

The reasons for the possible corrosion of bearings include: poor sealing device, intrusion by water, dirt, etc.

Bearings are not used for a long time, more than the rust period, lack of maintenance.

The surface roughness of metal is high.

Contact with corrosive chemical media, bearing cleaning is not clean, there is dirt on the surface, or contact the bearing with sweaty hands.

Ambient temperature and humidity and exposure to various environmental media;

Rust inhibitor failure or quality does not meet requirements.

Bearing machining form

The processing forms of deep groove ball bearing parts are as follows:

Multi-process processing: General bearing production needs 20 to 40 processes, more than 70.

Forming processing: The working surface of the bearing parts is a rotary forming surface, which is suitable for processing by forming method.

Precision machining: most of the surface of bearing parts should be grinding, grinding size and geometric accuracy are in μm units.

Deep groove ball suffix meaning

CN: normal group radial clearance; It is usually used only in combination with the following letters to indicate a narrow or offset gap range.

H: narrowed clearance range, equivalent to the upper half of the original clearance range.

L: narrowed clearance range, equivalent to the lower half of the original clearance range.

P: Offset clearance range, equivalent to the composition of the upper half of the original clearance range and the lower half of the next set of clearance ranges.

C2: The radial clearance is smaller than that of the ordinary group.

C3: Radial clearance is greater than that of the normal group.

C4: Radial clearance greater than C3.

C5: Radial clearance greater than C4.

DB: Two single-row deep groove ball bearings paired back to back.

DF: Two single-row deep groove ball bearings paired face to face.

DT: Two single-row deep groove ball bearings paired in series.

E: Enhanced design.

GJN: polyurea grease, NLGI consistency 2, temperature range -30 to +150 degrees (standard fill). GXN: polyurea grease, NLGI consistency 2, temperature range -40 to +150 degrees (standard fill). J: Stamped steel cage.

LHT23: Lithium base grease, NLGI consistency 2, temperature range -50 to +140 degrees (standard fill). LT: Lithium base grease, NLGI consistency 2, temperature range -55 to +110 degrees (standard fill). LT10: Lithium base grease, NLGI consistency 2, temperature range -50 to +90 degrees (standard fill). M: machined brass cage with steel ball guide. Different designs and materials are followed by digital identifiers such as M2.

MA: machined brass cage, outer ring guide.

MB: machined brass cage, inner ring guide.

MT33: Lithium base grease, NLGI consistency 3, temperature range -30 to +120 degrees (standard fill). MT47: Lithium base grease, NLGI consistency 2, temperature range -30 to +110 degrees (standard fill). N: The outer ring has a locking groove.

NR: The outer ring is provided with a stop groove and stop ring.

N1: There are grooves on the side of the outer ring (for matching with the stop device to prevent the outer ring from rotating).

P5: Dimensional accuracy and rotation accuracy meet ISO tolerance Class 5.

P6: Dimensional accuracy and rotation accuracy meet ISO tolerance class 6.

P52: P5+C2.

P62: P6+C2.

P63: P6+C3.

RS1: Nitrile diene rubber (NBR) contact seal with steel skeleton on one side.

RSH: Nitrile diene rubber (NBR) contact seal with steel skeleton on one side.

RSL: Nitrile diene rubber (NBR) low friction seal with steel skeleton on one side.

RZ: Nitrile diene rubber (NBR) low friction seal with steel skeleton on one side.

TH: Fiber reinforced phenolic resin cage (card type).

TN: Plastic molded nylon cage.

TN9: Plastic molded glass fiber reinforced nylon 6,6 cage.

VL0241: The outer surface of the outer ring is coated with alumina, and the insulation capacity is up to 1000VDC.

VL2071: The outer surface of the inner ring is coated with alumina, and the insulation capacity is up to 1000VDC.

WT: polyurea grease, NLGI consistency 2, temperature range -40 to +160 degrees (standard fill). Y: Stamped copper cage.

Z: One side with stamped steel dust cover.

ZNR: The outer ring is equipped with a stop groove and a stop ring, and the other side of the stop groove is equipped with a stamped steel dust cover.

2RS1: Nitrile butadiene rubber (NBR) contact seal holder with steel frame on both sides.

2RSH: Nitrile butadiene rubber (NBR) contact seal holder with steel frame on both sides.

2RSL: Nitrile butadiene rubber (NBR) low friction sealing ring with steel skeleton on both sides.

2RZ: Nitrile butadiene rubber (NBR) low friction seals with steel frames on both sides.

2Z: Stamped steel dust cover on both sides.

2ZNR: The outer ring is equipped with a stop groove and stop ring, and both sides are equipped with stamped steel dust cover. Common suffixes with ball notches:

C3: Radial clearance is greater than that of the normal group.

N: The outer ring has a locking groove.

NR: The outer ring is equipped with a stop groove and a stop ring.

Z: One side with stamped steel dust cover.

ZNR: The outer ring is equipped with a stop groove and a stop ring, and the other side of the stop groove is equipped with a stamped steel dust cover.

2Z: Stamped steel dust cover on both sides.

2ZNR: The outer ring is equipped with a stop groove and stop ring, and both sides are equipped with stamped steel dust cover. The meaning of stainless steel suffix:

R: Outer ring with flange.

VT378: non-toxic grease (accidental contact with food ingredients).

2RS1: Nitrile butadiene rubber (NBR) contact seals with steel frames on both sides.

2Z: Stamped steel dust cover on both sides.

2ZR: Stamped steel dust cover on both sides and outer ring with flange.

Aligning ball bearings

Aligning ball bearing has two kinds of structure, cylindrical hole and conical hole, cage material is steel plate, synthetic resin and so on. It is characterized by the spherical raceway of the outer ring, with automatic centering, which can compensate for the error caused by different concentricity and shaft deflection, but the relative inclination of the inner and outer ring shall not exceed 3 degrees.

intro

Aligning ball bearings are bearings equipped with spherical ball bearings between the inner ring of two raceways and the outer ring of a spherical raceway.

The center of curvature of the raceway surface of the outer ring is consistent with the center of the bearing, and has a similar aligning function to the automatic aligning ball bearing. When the shaft and housing are flexed, they can be automatically adjusted without increasing the bearing burden. Aligning ball bearings can withstand radial loads and axial loads in both directions. Large radial load capacity, suitable for heavy loads, impact loads.

The inner diameter of the inner ring is a cone hole bearing, which can be installed directly. Or use a tight sleeve, disassembly cylinder installed on the cylindrical shaft. The cage uses steel plate stamping cage, polyamide forming cage and copper alloy turning cage.

The characteristics of aligning ball bearing aligning ball bearing has two kinds of structure, cylindrical hole and conical hole, cage material is steel plate, synthetic resin and so on. It is characterized by the spherical raceway of the outer ring, with automatic centering, which can compensate for the error caused by different concentricity and shaft deflection, but the relative inclination of the inner and outer ring shall not exceed 3 degrees.

Aligning ball bearing can bear large radial load, but also can bear a certain axial load. The outer ring raceway of this kind of bearing is spherical, so it has aligning performance. When the shaft is bent or tilted by force, the relative inclination between the inner ring center line and the outer ring center line does not exceed 1° ~ 2.5°, the bearing can still work normally.

Bearing series

Micro series: 10x, 12x, 13x

General series: 12xx, 13xx, 22xx, 23xx

Similar product

Sweden SKF aligning ball bearings

German FAG aligning ball bearings

Japan NIN aligning ball bearing

use

Aligning ball bearing is suitable for bearing heavy load and impact load, precision instrument, low noise motor, automobile, motorcycle, metallurgy, rolling mill, mining, petroleum, paper making, cement, sugar pressing and other industries and general machinery.

Basic common sense

Aligning ball bearing product characteristics: mainly bear radial load, while can bear small axial load. The axial displacement of the shaft (housing) is limited within the clearance limit, with automatic aligning performance, allowing the internal and external relative tilt is not large under the condition of normal work, suitable for supporting the seat hole can not strictly ensure the coaxiality of the parts.

Aligning ball bearing structure: The aligning ball bearing with dust cover and sealing ring has been filled with appropriate grease during assembly, and should not be heated or cleaned before installation, and no lubrication is required during use, and can adapt to the operating temperature between -30°C and +120°C.

Aligning ball bearing main uses: suitable for precision instrument, low noise motor, automobile, motorcycle and general machinery, etc., is the most widely used class of bearings in the machinery industry.

Technical requirement

Classification summary of rolling bearings:

Classified by rolling bearing structure type

According to the direction of the load that can be borne or the nominal contact Angle, it is divided into:

Radial bearing

Thrust bearing

According to the type of rolling element, it is divided into:

Ball bearing

Roller bearing

According to whether the heart can be adjusted during work, it is divided into:

Aligning bearing

Non-aligning bearing

According to the number of columns of rolling elements, it is divided into:

Single row bearing

Double row bearing

Multiple row bearing

According to its parts can be separated, divided into:

Separable bearing

Non-separable bearing

According to its structural shape can also be divided into: a variety of structural types.

According to the rolling bearing size is divided into:

Miniature bearing

Small bearing

Small and medium bearing

Medium and large bearing

Large bearing

Oversize bearing

Suffix definition

C3: Radial clearance is greater than normal clearance

K: 1/12 taper taper hole

K30:1/30 taper taper hole

M: Steel ball guided machined brass solid cage

2RS: with two sealing caps

TV: Glass fiber reinforced polyamide (nylon) solid cage guided by steel ball

Job requirement

For bearing configurations with heavy loads, harsh working conditions or special sealing requirements, built-in contact sealed aligning roller bearings can be used. The bearing dimensions are exactly the same as unsealed bearings, and can be used in many cases instead of unsealed bearings. The alsetting Angle is allowed to be 0.5°, and the working temperature is -20°C~110°C. The bearing has been filled with an appropriate amount of lithium based anti-rust grease, and grease can also be added according to user requirements. According to the inner ring with or without rib and the cage used, it can be divided into two basic types: C type bearing is characterized by the inner ring without rib and the use of steel plate stamping cage, CA type bearing is characterized by the inner ring on both sides of the rib and the use of car solid cage. This type of bearing is especially suitable for work under heavy loads or vibration loads. Self-aligning roller bearing A bearing equipped with a drum roller between an inner ring with two raceways and an outer ring with spherical raceways. The center of curvature of the raceway surface of the outer ring is consistent with the center of the bearing, and has a similar aligning function to the automatic aligning ball bearing. When the shaft and shell are flexing, it can be automatically adjusted to bear radial load and axial load in both directions. Large radial load capacity, suitable for heavy loads, impact loads. The inner diameter of the inner ring is a cone hole bearing, which can be installed directly. Or use a tight sleeve, disassembly cylinder installed on the cylindrical shaft. The cage uses steel plate stamping cage, polyamide forming cage and copper alloy turning cage.

Cylindrical roller bearings

The rolling element is a centripetal rolling bearing with a cylindrical roller. Inside cylindrical roller bearings, the rollers are arranged to cross each other vertically by approximately 90° (this is the basis for the name of cross roller bearings). A spacer or isolating block is provided between the rollers to prevent the rollers from tilting or rubbing against each other, thereby effectively avoiding the increase in rotational torque.

Basic information

cylindrical roller bearing (cylindrical roller bearing)

summarize

The cylindrical roller forms line contact with the raceway, which has a large load capacity and is mainly used to bear radial load. The friction between the roller and the inner and outer ring is very small, which is suitable for high-speed rotation. According to whether the inner and outer rings have guards, they can be divided into NU, NJ, NUP, N, NF and other single-row cylindrical roller bearings, and NNU, NN and other double-row cylindrical roller bearings. The inner and outer rings of this type of bearing can be separated.

Cylindrical roller bearings with inner or outer rings without guards, whose inner and outer rings can move relative to each other along the axis, so they can be used as free-end bearings. For a cylindrical roller bearing with a double rib on one side of the inner ring and the outer ring, and a single rib on the other side of the ring, it can withstand a certain level of one-way axial load. Steel sheet cages or copper alloy solid cages are usually used, but polyamide formed cages are also used.

Bearing characteristics

1. The cylindrical roller and the raceway are in line contact or corrected line contact, which has a large radial bearing capacity and is suitable for bearing heavy loads and impact loads.

2. The friction coefficient is small, suitable for high-speed operation, and its limit speed is close to the deep groove ball bearing.

3. Type N and type NU can move along the axis, can adapt to the change of the relative position of the shaft and the housing caused by thermal expansion or installation error, and can be used as free end support.

4. The relative deviation of the outer ring axis is strictly controlled to avoid contact stress concentration.

5. The inner ring or outer ring can be separated for easy installation and disassembly.

Product characteristics

The cylindrical roller forms line contact with the raceway and has strong radial load capacity. It can withstand heavy loads and impact loads, and is also suitable for high-speed rotation. After the improved design, the bearing capacity is improved. The new structural design of the rib and roller end face enhances the axial bearing capacity, improves the lubrication conditions of the contact area between the roller end face and the rib, and improves the service performance.

Scope of application

Widely used in large and medium-sized motor, rolling stock, machine tool spindle, internal combustion engine, generator, gas turbine, reducer, rolling mill, vibrating screen and lifting machinery and other fields.

Structural form

Bearing structure form

Classification according to the number of columns containing rollers

Cylindrical roller bearings can be divided into different structures such as single row, double row and multi-row cylindrical roller bearings according to the different number of columns installed with rolling elements. Different structural bearings are also reflected in the position design of the rib. Commonly used cylindrical roller bearings include but are not limited to the following forms:

Single row cylindrical roller bearings: Single row cylindrical roller bearings are separable bearings, easy to install and remove, both rings can be used in a tight fit, the modified contact line between the roller and the raceway can reduce stress concentration.

Double row cylindrical roller bearings: Double row cylindrical roller bearings are floating bearings, and their separability makes installation and disassembly very convenient. Both rings can be fitted tightly. Double row cylindrical roller bearings allow little inclination.

Single row bearing: single row cylindrical roller bearing (type N, NU); NJ, NF type; NUP, NFP type; Type NH (NJ+HJ)

Double row bearings: double row cylindrical roller bearings (NN, NNU type; NNF type)

Four row bearings: four row cylindrical roller bearings (FC type; FCD type)

Influencing factor

Vibration: In daily use, vibration is very sensitive to bearing damage, such as peeling, indentation, rust, cracks, wear, etc., will be reflected in the bearing vibration measurement. Therefore, by using a special bearing vibration measuring device (such as a frequency analyzer, etc.), the size of the vibration can be measured, and the specific situation of the anomaly can be inferred through the frequency distribution. The measured value varies due to factors such as the use conditions of the bearing or the installation position of the sensor, so it is necessary to analyze and compare the measured value of each machine in advance to determine the judgment standard.

Temperature: High temperature often indicates that the cylindrical roller bearing is in an abnormal state. High temperature will cause damage to the lubricant of the bearing. Sometimes bearing overheating can be attributed to poor lubrication of the bearing. If the bearing is operated for a long time at a temperature of more than 125 ° C, the bearing life will be reduced. Causes of high temperature bearings include: insufficient or excessive lubrication, bearing raceway contains impurities, limit speed is too high, bearing long-term overload operation.

Self-aligning roller bearings

An aligning roller bearing is a specially designed bearing that is equipped with a drum roller between the inner ring and the outer ring with two raceways, and the outer ring raceways are spherical in shape.

summarize

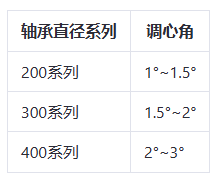

Aligning roller bearings contain two rows of rollers, which are mainly used to carry radial loads, but also can withstand axial loads in any direction. They have a high radial load bearing capacity and are particularly suitable for heavy loads or vibration environments, but are not suitable for pure axial loads. The raceway of the outer ring of this kind of bearing is designed to be spherical shape, so it has good aligning performance and can compensate the coaxial error of the shaft.

peculiarity

Self-aligning roller bearings are equipped with two rows of symmetrical spherical rollers, the outer ring has a common spherical raceway, and the inner ring has two raceways tilted at an Angle to the bearing axis. Even in the case of shaft bending or installation deviation, this type of bearing can work normally, its aligning capacity will vary according to different size series, usually allowed aligning Angle range between 1° and 2.5°. In addition, such bearings can not only withstand large radial loads, but also withstand two-way axial loads, and have a certain impact resistance. However, due to the relatively low allowable operating speed, the choice in high-speed applications is limited.

According to the shape of the cross section of the roller, the aligning roller bearing can be divided into two kinds of structures: symmetrical spherical roller and asymmetric spherical roller. Asymmetrical self-aligning roller bearings are mainly used for the maintenance of old equipment, and in newly designed equipment, symmetrical self-aligning roller bearings are more inclined to be used. After a comprehensive design improvement and parameter optimization, compared with the earlier version, the self-aligning roller bearings produced by Hunan Wa Fangdian Bearing Manufacturing Co., Ltd. can withstand greater axial loads and operate at lower temperatures, which is more suitable for operation at higher speeds.

structure

Aligning roller bearings are divided into two kinds according to the shape of the inner ring: cylindrical inner hole and conical inner hole. The taper of the hole in the cone is 1:12 (suffix K) and 1:30 (suffix K30) respectively. When this type of bearing is used with a conical shaft, the radial clearance of the bearing can be adjusted by adjusting the position of the inner ring.

Cage type

Commonly used cages include: stamped steel reinforced cages (suffix E), stamped steel reinforced cages (suffix CC), glass fiber reinforced polyamide 66 cages (suffix TVPB), machined brass two-piece cages (suffix MB) and machined brass integral cages (suffix CA).

use

This kind of bearing is widely used in various industrial fields, such as paper making machinery, reducer, railway vehicle, rolling mill gear box, crusher, vibrating screen, printing machinery, woodworking machinery and all kinds of industrial reducer.

Install

Self-aligning roller bearings can be fitted with drum rollers between an inner ring with two raceways and an outer ring with spherical raceways. The center of curvature of the outer raceway is consistent with the center of the bearing, so that it has the aligning function similar to the automatic aligning ball bearing. The radial and axial loads can be adjusted automatically when the shaft and housing are flexed. These bearings have a large radial bearing capacity and are suitable for use under heavy load and impact load conditions. For the bearing with the inner diameter of the inner ring for the cone hole, it can be installed directly, or it can be installed on the cylindrical shaft using the tight sleeve and the disassembly cylinder. The cage generally adopts steel plate stamping cage, polyamide forming cage and copper alloy turning cage.

Axial clearance adjustment

The axial clearance of the self-aligning roller bearing can be adjusted by adjusting the nut on the journal, adjusting the thread in the gasket and bearing seat hole, or using a pre-loaded spring. The size of the axial clearance depends on the installation arrangement of the bearing, the distance between the bearings and the material of the shaft and the bearing seat, and the specific size needs to be determined according to the actual working conditions. For self-aligning roller bearings bearing high load and high speed rotation, the influence of temperature rise on axial clearance should be considered when adjusting the clearance, and the axial clearance should be appropriately increased to compensate for the reduction caused by thermal expansion. For bearings with low speed or subjected to vibration, no clearance installation or pre-load installation should be used to ensure good contact and uniform load distribution between rollers and raceways to avoid damage to rollers and raceways due to vibration impact. The adjusted axial clearance can be checked by a dial gauge.

Needle roller bearing

needle bearing is a type of bearing with elongated cylindrical rollers that are very elongated in relation to their diameter. These rollers are called needle rollers. Although the cross section is small, the needle roller bearing can still withstand higher loads. Needle roller bearings are equipped with slender rollers (roller diameter D≤5mm, L/D≥2.5, where L is the length of the roller), so their radial structure is very compact. While the inner diameter and bearing capacity are the same as other types of bearings, the outer diameter is minimal, making it ideal for applications where radial mounting size is limited.

peculiarity

Needle roller bearings are equipped with slender rollers (roller diameter D≤5mm, L/D≥2.5, where L is the length of the roller), so their radial structure is compact. While the inner diameter and bearing capacity are the same as other types of bearings, the outer diameter is minimal, making it ideal for applications where radial mounting size is limited. Depending on the application scenario, you can choose bearings without inner rings or components consisting only of needle rolls and cages. At this time, the journal surface and shell hole surface matched with the bearing directly act as the inner and outer rolling surface of the bearing. In order to ensure that the bearing capacity and operating performance are comparable to those of bearings with inner rings, the hardness, machining accuracy and surface quality of the raceway surface of the shaft or housing hole should be similar to that of the raceway of the bearing ring. This bearing can only bear radial loads.

type

In addition to bearings listed in the catalog suitable for general engineering, such as: In addition to open stamped outer ring needle roller bearings, closed stamped outer ring needle roller bearings, needle roller bearings with inner ring and without inner ring, and full loaded needle roller bearings with cage and without cage, Hunan Wafangdian Bearing Manufacturing Co., Ltd. also provides various types of needle roller bearings. Including needle cage assembly, needle roller bearings without rib, self-aligning needle roller bearings, combined needle roller/ball bearings, combined needle roller/thrust ball bearings and combined needle roller/cylindrical roller thrust bearings, etc.

Supporting roller

STO - The outer ring has no retaining edge, and the inner ring supports the roller.

RNA22... 2RS - Double-sided seal without inner ring support roller.

NA22... 2RS - Double-sided seal with inner ring supporting roller.

NATR/NATV - Flat retaining ring axial guide support roller, NATV type is full needle roller type.

NUTR - Roller guide support roller, full roller type.

CRY - British flat ring axial guide support roller.

Stamped outer ring

The stamped outer ring needle roller bearing is a needle roller bearing with a thin stamped outer ring. Its main feature is low section height and high load bearing capacity. It is mainly used for the bearing configuration with compact structure, low cost and the hole in the bearing box cannot be used as the raceway of the needle roller cage assembly. Bearings and bearing boxes shall be installed in an interference fit. If you can eliminate the shoulder, stop ring and other axial positioning functions, then the bearing box hole can be designed extremely simple and economical.

Needle roller bearing with oil seal stamped outer ring

In the case that the oil seal cannot be installed due to space constraints, Hunan Wa Fangdian Bearing Manufacturing Co., Ltd. provides needle roller bearings with oil seal stamped outer ring with open end or closed end. These bearings are equipped with polyurethane or synthetic rubber friction oil seals filled with good rust resistance of lithium grease, suitable for the operating temperature range of -20 to +100 ° C. The inner ring of the bearing with oil seal is 1mm wider than the outer ring, which makes it possible to ensure the good working condition of the oil seal and prevent the bearing from being contaminated even if the shaft has a slight displacement relative to the bearing box. The bearing inner ring also has a lubrication hole, which can be supplemented with lubrication from the outer ring or the inner ring according to the needs of the bearing configuration.

sort

centripetal needle roller and cage assembly

NA,NKI type needle roller bearings

RNA,NK type needle roller bearing without inner ring

HK type stamped outer ring needle roller bearings

BK type stamped outer ring needle roller bearings

English model

Metric series: HK, BK, F, FH, FY, MF, MFH, MFY; TA.. Z, TLA... Z, TAM, TLAM, YT, YTL.

British series: SCE, BCE, SCH, BCH, SN, B, BH, M, MH; BA... Z, BHA... Z, BAM, BHAM, YB, YBH.

Example: HK XX YY model tangent circle diameter XX height YY

Solid ferrule

A solid ring needle roller bearing consists of one or two rings and a needle roller with a cage. According to different applications, it can be divided into bearings with inner ring or without inner ring. Therefore, the solid ring needle roller bearing can meet the needs of light weight, small space occupation and large power transmission. Solid ring needle roller bearings have smaller volume and higher load capacity.

Combined type

Combined needle roller bearing is a bearing unit composed of radial needle roller bearing and thrust bearing components. It has compact structure, small volume and high rotation accuracy, and can bear a certain axial load while bearing a high radial load. The product structure is diverse, adaptable and easy to install. Composite needle roller bearings are widely used in machine tools, metallurgical machinery, textile machinery and printing machinery and other mechanical equipment, which can make the overall design of the mechanical system more compact and flexible.

Thrust type

The thrust bearing consists of a thrust cage assembly with a needle roller or cylindrical roller or ball and a thrust washer. Needle rollers and cylindrical rollers are held and guided by the thrust cage. When used with different series of DF thrust bearing washers, a variety of combinations are available for bearing configurations. Thanks to the use of high-precision cylindrical rollers (needle rollers), the contact length is increased, so high load capacity and high stiffness can be obtained in a small space. Another advantage is that if the adjacent part surface is suitable as a raceway surface, the gasket can be omitted, resulting in a more compact design.

Install

When installing a fully loaded needle roller bearing, an auxiliary sleeve is usually used. At this time, the auxiliary roller or auxiliary sleeve supports the needle roller to prevent the needle from falling. The journal lifts the needle roller with its own chamfer, and as the needle roller bearing slowly moves inward on the journal, the auxiliary roller or auxiliary sleeve gradually exits until it is installed in place.

Compare

1. The friction coefficient of rolling bearings is much lower than that of plain bearings, and the transmission efficiency is higher. Generally, the friction coefficient of plain bearings is 0.08-0.12, while the friction coefficient of rolling bearings is only 0.001-0.005.

2. Rolling bearings have been standardized, serialized and generalized, suitable for large-scale production and supply, and extremely convenient to use and maintain.

3. Rolling bearings are made of bearing steel and have been heat treated, so they have higher mechanical properties and longer service life, and can also save the more expensive non-ferrous metals required for the manufacture of plain bearings.

4. The internal clearance of rolling bearings is small, and the processing accuracy of each component is higher, so the running accuracy is higher. In addition, the rigidity of the bearing can be enhanced by preloading, which is very important for precision machinery.

5. Some rolling bearings can bear radial load and axial load at the same time, thus simplifying the structure of the bearing support.

6. Due to the high transmission efficiency of the rolling bearing, the heat generated is less, so the consumption of lubricating oil can be reduced, and the lubrication maintenance is easier.

7. Rolling bearings can be easily applied to any direction of the shaft in space.

Matters needing attention

Needle roller bearings have high load capacity and are suitable for applications with limited installation size. The journal surface is hardened as a rolling surface, and the bearing is pressed into the seat hole without the need for axial positioning. Appropriate amount of grease should be injected before installation, usually, no need to lubricate after installation. BK type bearing is suitable for the support of the journal without an extended end, the end face closure plays a sealing role, and can withstand small axial swimming.

Cause of damage

About one third of needle roller bearing damage is caused by fatigue damage, one third of needle roller bearing damage is caused by poor lubrication, and the remaining one third is caused by pollutants entering the bearing or improper disposal of equipment.

Fine dust: Clean the bearing and its surrounding environment, even the tiny dust invisible to the naked eye is a deadly killer of bearings, it will increase bearing wear, vibration and noise.

stamping: Strong stamping may cause damage to the needle roller bearing when using the equipment, or directly hit the bearing with a hammer to transfer pressure through the roller.

Non-professional tool installation: Use special tools whenever possible to avoid using tools such as cloth and staple fibers. Even in laboratory tests or actual use, the appearance of the same needle roller bearings, under the same working conditions, its actual life will be very different.

Disassembly method

Tapping method

When using the tapping method, the tapping force is usually applied to the inner ring of the bearing to avoid directly tapping the rolling element and cage of the bearing, so as not to cause damage. When the bearing is located at the end of the shaft, a copper rod or other soft metal material with a diameter smaller than the inner diameter of the bearing can be used to hold the shaft end, a pad is placed below it, and then the bearing can be removed by gently tapping. When using this method, it is necessary to pay attention to the placement of the pad to ensure that the point of emphasis is correct.

Hot disassembly

Suitable for removing tight fit bearings. First of all, the oil heated to about 100°C is poured on the bearing to be removed, and after the bearing ring is heated and expanded, the bearing can be easily pulled out using a puller.

Push-up method

Using a press to push the bearing is a smooth and reliable method without damaging the machine or the bearing. The press can be manually operated, mechanical or hydraulic. When using, it should be noted that the focus point should be located in the center of the shaft to avoid pressure bias.

Pull-out method

When using a special puller to remove the bearing, just rotate the handle and the bearing will be slowly pulled out. When removing the outer ring of the bearing, the Angle of the two feet of the puller should be opened outward; When removing the bearing inner ring, the two feet of the puller should be inward and stuck on the end face of the bearing inner ring.

Advantages and applicability of needle roller bearings

Needle roller bearings are equipped with slender rollers (roller length is usually 3 to 10 times the diameter, the diameter is generally not more than 5mm), so its radial structure is very compact. When the inner diameter size and load capacity are the same as other types of bearings, the outer diameter is minimal, especially suitable for applications where the radial mounting size is limited. Needle roller bearings according to the use of different occasions, its processing accuracy and surface quality should be matched with the bearing ring to ensure good performance. Needle roller bearing is a bearing unit composed of a radial needle roller bearing and a thrust bearing component.

Spiral roller bearings

Overview of spiral roller bearings

The rolling element of spiral roller bearing adopts spiral roller wound by steel strip. Therefore, this type of bearing is called spiral roller bearing. This kind of bearing has large elasticity and radial clearance, can withstand large impact radial load, but can not withstand axial load, and the limit speed is low. They are suitable for parts where rotation accuracy is not required and often subjected to large impact loads. During installation, a maximum tilt Angle of 0.5° is allowed between the inner ring axis and the outer ring axis. Due to the elastic deformation characteristics of this type of bearing, precise rotation accuracy cannot be guaranteed in the working state, so spiral roller bearings have only one ordinary level of accuracy, and there are no other precision level options.

Characteristics of spiral roller bearings

The inner and outer rings of the bearing are made of alloy steel strips rolled up and processed by special processing and assembly processes. The spiral gap on the surface of the inner and outer rings of the bearing allows the lubricating oil to be evenly distributed on the working surface of the entire bearing. Even under the working conditions of large temperature difference, the matching size of the bearing can be automatically compensated.

Application field

Spiral roller bearings are widely used in major steel mills.

Manufacturing process

The inner and outer rings of the bearing are made of alloy steel strips rolled up and processed by special processing and assembly processes. The spiral gap on the surface of the inner and outer rings of the bearing allows the lubricating oil to be evenly distributed on the working surface of the entire bearing. Even under the working conditions of large temperature difference, the matching size of the bearing can be automatically compensated. Hunan Wafangdian Bearing Manufacturing Co., Ltd. focuses on the design and production of bearings used in plate guide rolls, as well as the design of bearings required for various parts of arc casting machinery.

advantage

Material characteristics: This type of bearing is made of spring steel, which has an annealing temperature of 350°C, which means that it is more resistant to hardness loss in high-temperature operations than ball bearing steel (100C6), which has an annealing temperature of 180°C.

easy to install: spring steel has good elasticity, easy to install. The inner ring can be installed in any position by two hook wrenches, and the internal tension of the inner ring makes it secure to the shaft. It is relatively easy to process an inner ring with a tolerance of h9 or h11 using an elastic material.

Dirt resistance: These bearings are durable and not susceptible to dirt, iron filings, water and weak acids formed by iron filings and water. The large diameter of the spiral ring provides enough space for the rolling parts, which can press impurities and foreign substances into the spiral gap of the spiral ring by rolling, keeping the moving surface of the bearing clean as it turns.

Reusable outer rings: One of the main advantages of spiral bearings is that the outer rings can be reused many times. In case of damage or bending due to temperature effects, the outer ring can be reworked. In this case, only the bearing seat needs to be adjusted. This design means that only the outer spiral ring needs to be replaced rather than the entire bearing, and all other bearing components can be reused. The adjustment of the bearing housing can be done by increasing the diameter size in increments of 1 mm. For example, when the inner diameter is increased from 105mm to 106mm, the outer diameter of the spiral outer ring needs to be correspondingly increased by 1mm for installation. This process can be repeated up to a diameter of 110mm, which means that the outer spiral can be repeated five times, a significant cost savings, especially when all other bearing parts can be reused six times. It is a bearing unit composed of a needle roller bearing and a thrust bearing component.

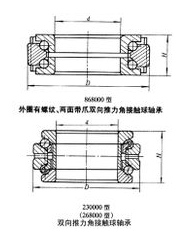

Angular contact ball bearing

Overview of angular contact ball bearings

Angular contact ball bearings can withstand both radial and axial loads and work at higher speeds. The larger the contact Angle, the stronger the axial bearing capacity. High precision and high speed bearings usually have a contact Angle of 15 degrees. Under the action of axial force, the contact Angle will increase.

concept

Single-row angular contact ball bearings can only bear axial load in one direction, and additional axial force will be generated when bearing radial load. They can only limit the axial displacement of the shaft or housing in one direction. The contact Angle of angular contact ball bearings is usually 40 degrees, so they can withstand large axial loads. This type of bearing is designed to be non-separable and has different heights on both sides of the inner and outer rings. To increase the carrying capacity, the shoulder on one side is machined lower to accommodate more balls.

Double row angular contact ball bearings can withstand large radial loads, mainly radial and axial combined loads and torque loads, limiting the axial displacement of both sides of the shaft. The tilt Angle between the inner and outer rings of double row angular contact ball bearings is limited, and the maximum allowable tilt Angle should ensure that no excessive additional stress is generated inside the bearing. If there is a tilt between the inner and outer rings of the bearing, it will affect the life of the bearing, resulting in a decrease in the running accuracy of the bearing and an increase in noise. Double row angular contact ball bearings generally use nylon cages or brass solid cages. During installation, it should be noted that although the bearing can withstand two-way axial loads, if there is a ball loading gap on one side, it should be ensured that the main axial load passes through the side without a gap.

When installing double ball bearings in pairs, the outer rings of a pair of bearings are relative, that is, the wide end faces the wide end face and the narrow end faces the narrow end face. This avoids causing additional axial forces and ensures that the shaft or housing is limited within the range of axial clearance.

peculiarity

Bearings in general assembly: Specially machined, when bearings are tightly installed, any combination can achieve a given internal clearance or preload, as well as an average load distribution, without the use of gaskets or similar devices.

Paired bearings are used when the load carrying capacity of a single bearing is insufficient (using series configuration) or when a combined load or axial load acting in two directions is required (using back-to-back or face to face configuration).

Bearings of the basic design (which cannot be used as general assembly) for the configuration of individual bearings. The basic design of single-row angular contact ball bearings is mainly used in configurations with only one bearing per position. Their widths and protrusions meet common tolerances and are therefore not suitable for mounting two single-row angular contact ball bearings close together.

Accuracy class: The accuracy class of angular contact ball bearings includes dimensional tolerances and rotation accuracy, expressed from low to high as P0 (normal), P6(P6X), P5, P4, P2. In addition, European and American brands also use P3, P7, and P9 to indicate accuracy levels, P3 is equivalent to P6 of ISO and JIS standards, P7 is equivalent to P4, and P9 is equivalent to P2.

Type: There are several types of angular contact ball bearings: 7000C (∝=15°), 7000AC (∝=25°) and 7000B (∝=40°). The lock of this bearing is on the outer ring, and the inner and outer rings cannot be separated, and it can withstand the combined radial and axial loads as well as the axial loads in one direction. The contact Angle determines the ability to bear axial load, and the larger the contact Angle, the higher the ability to bear axial load. This bearing can limit the axial displacement of the shaft or housing in one direction.

Single row angular contact ball bearings can only withstand one direction of the axial load, in the radial load, will cause additional axial force, must apply the corresponding reverse load, so this bearing is usually used in pairs. Double row angular contact ball bearings can bear large radial and axial bidirectional combined loads and torque loads, which are mainly radial loads. It can limit the axial displacement of the shaft or housing, and the contact Angle is 30 degrees.

Installation and configuration

back-to-back configuration, with the rear designation DB, the load line of the bearings in this configuration is separated from the bearing shaft. It can withstand axial loads acting in two directions, but the load in each direction can only be borne by one bearing. Back-to-back mounted bearings provide a bearing configuration with high rigidity and can withstand overturning moments.

In face to face configuration, with rear designation DF, the load lines of the bearings paired face to face meet towards the bearing shaft. It can withstand axial loads acting in two directions, but the load in each direction can only be borne by one bearing. This configuration is not as rigid as back-to-back pairing and is less suitable for withstanding overturning moments.

series configuration, the rear code is DT, series configuration, the load line is parallel, radial and axial load is evenly shared by the bearing. However, the bearing group can only withstand the axial load acting in one direction. If the axial load acts in the opposite direction, or if there is a compound load, a third bearing that is adjusted relative to the tandem pair bearing must be added.

Load capacity (simplified)

For any configuration of standard bearings and back-to-back or face to face configuration of Hunan Wwafangdian Bearing Manufacturing Co., Ltd. Explorer bearings, the basic dynamic load rating is 1.62xC single bearing.

For the Explorer bearings of Hunan Wa Fangdian Bearing Manufacturing Co., Ltd. in series configuration, the basic rated dynamic load is 2xC single bearing.

Basic static load rating is 2xCo single bearing.

Fatigue limit load is 2xPu single bearing.

Type of structural deformation

Double row angular contact ball bearings can bear the combined load of radial and axial loads at the same time, limiting the axial displacement of both sides of the shaft. Compared with two-way thrust ball bearings, this bearing has a higher limit speed, a contact Angle of 32 degrees, good rigidity, and can withstand large overturning moment, and is widely used in the front wheel hub of the car (some models also use double-row tapered roller bearings of the same size).

Type A: Standard design for bearings with an outer diameter of 90mm or less. There is no ball filling gap, so it can withstand equal two-way axial loads. Light glass fiber reinforced nylon 66 cage, bearing temperature rise is very small.

Type A: Standard design for bearings with an outer diameter greater than 90mm. One side has a ball notch and is equipped with a Z-plate pressed cage or a brass solid cage.

E type: is a reinforced structure, one side with a ball gap, can be loaded more steel balls, so the bearing capacity is higher.

Double row angular contact ball bearings of type A design and type E design are available with either dust cover (non-contact) or seal (contact) on either side. The inside of the sealed bearing is filled with anti-rust lithium grease, and the operating temperature is generally between -30 degrees and 110 degrees. No more lubrication is required during use, and no more heating before installation.

Main use

Single row angular contact ball bearing: machine tool spindle, high frequency motor, gas turbine, centrifugal separator, small automobile front wheel, differential pinion shaft, booster pump, drilling platform, food machinery, dividing head, repair welding machine, low noise type cooling tower, electromechanical equipment, painting equipment, machine tool groove plate, arc welding machine

double row angular contact ball bearing: oil pump, Roots blower, air compressor, transmission, fuel injection pump, printing machinery, planetary reducer, extraction equipment, cycloidal reducer, food packaging machinery, electric welding machine, electric soldering iron, square box, gravity spray gun, wire stripping machine, half shaft, inspection and analysis equipment, fine chemical machinery

Installation tips

High-speed precision angular contact ball bearings are mainly used for high-speed rotating occasions with light load, requiring bearings with high precision, high speed, low temperature rise and low vibration and certain service life. The supporting parts of high-speed motorized spindle are often installed in pairs and are the key accessories of high-speed motorized spindle of internal surface grinding machine.

o Main technical indicators:

bearing accuracy index: more than GB/307.1-94 P4 accuracy

High-speed performance index: dmN value 1.3~1.8×10^6/min

Service life (average) : >1500 h

The service life of high-speed precision angular contact ball bearing is very much related to the installation, should pay attention to the following matters:

o Bearing installation should be carried out in a dust-free and clean room, bearings should be carefully selected, bearing spacers should be ground, under the premise of maintaining the height of the inner and outer spacers, the parallelism of the spacers should be controlled below 1um.

o bearings should be cleaned before installation, cleaning the inner ring slope up, hand sensing flexible, no sense of stagnation, after drying, into the specified amount of oil, such as oil mist lubrication should be put into a small amount of oil mist oil.

o Bearings should be installed with special tools, the force is uniform, it is strictly prohibited to knock.

Bearing storage should be clean and ventilated, no corrosive gas, relative humidity does not exceed 65%, long-term storage should be regular rust prevention.

Suffix definition

B: Modified internal structure

MP: machined window brass cage

TVP: glass fiber reinforced nylon cage

UA: General structural design for paired mounting bearings, small axial clearance bearing groups

UO: Universal structural design for paired mounting bearings, zero axial clearance bearing groups

DA: Double half inner ring (double row angular contact ball bearing)

TVH: glass fiber reinforced polyamide cage, steel ball guide

Maintenance method

When the bearing runs to a certain period (or maintenance cycle), the bearing is removed completely.

Soak the bearing in diesel oil or kerosene for cleaning. If there is technical condition, it is best to open the seal cover for cleaning.

Dry the cleaning oil after cleaning, and check the appearance for damage.

Fix a bearing at one end of a stick (preferably a hollow pipe) of about 150mm length and diameter equal to the inner diameter of the angular contact ball bearing.

While rapidly turning the bearing by hand, hold the other end of the stick against the ear or the microphone of the audio amplifier to identify the bearing rotation noise.

After fixing the bearing, flip the wood rod horizontally to check whether the bearing is worn and loose.

Bearings with serious loosening, excessive rotation noise and serious defects should be eliminated and replaced with the same model.

Take a bucket and melt appropriate amount of grease (high quality yellow dry oil) with gentle heat (do not overheat). Put the tested bearings in the bucket and soak until no bubbles overflow. Remove the bearing before the grease cools, and the amount of residual grease is less. Remove the angular contact ball bearing after the grease is cooled, and there is a large amount of residual grease. Determine the amount of residual grease as needed.

Wipe the grease on the outside of the bearing with a soft cloth or toilet paper, and install the bearing on the pulley in its original state. The maintenance work is finished immediately.

Tapered roller bearings

Tapered roller bearings are a type of separated bearing with tapered raceways in both the inner and outer rings. These bearings are divided into different structural forms such as single row, double row and four row according to the number of rollers. Single-row tapered roller bearings can withstand both radial and unidirectional axial loads. When a radial load is borne, an axial component is generated, so it is usually balanced by another bearing that can withstand the reverse axial force.

definition

The ability of single-row tapered roller bearings to withstand axial load depends on the contact Angle (that is, the Angle of the outer ring raceway), the greater the contact Angle, the stronger the axial load capacity. Among the tapered roller bearings produced by Hunan Wa Fangdian Bearing Manufacturing Co., LTD., the most commonly used are single-row tapered roller bearings. Small size double row tapered roller bearings are used in the front wheel hub of the car. Four row tapered roller bearings are used in heavy machinery such as large cold and hot rolling mills.

Structural characteristics

Tapered roller bearing type code 30000, for the separation type bearing. Under normal circumstances, especially within the size range specified in GB/T307.1-94 "Rolling bearing radial Bearing Tolerance", the outer ring and the inner component of tapered roller bearings can be universally interchangeable.

The Angle of the outer ring and the diameter of the outer raceway have been standardized and are not allowed to be changed during design and manufacturing. This allows the outer ring and inner components of tapered roller bearings to be interchangeable on a global scale.

sort

A single-row tapered roller bearing comprises an outer ring and an inner ring assembly enclosed by a basket cage. The outer ring can be separated from the inner ring assembly. In accordance with the requirements of the ISO tapered roller bearing dimension standard, any standard type of tapered roller bearing outer or inner ring assembly should be able to be internationally interchangeable with the same type of outer or inner ring assembly.

The outer ring (or inner ring) of a double-row tapered roller bearing is a whole. The small end faces of the two inner rings (or outer rings) are opposite, and there is a spacer in the middle. The clearance is adjusted by adjusting the thickness of the spacer ring, and it can also be used to adjust the pre-interference of the double-row tapered roller bearing.

The performance of four-row tapered roller bearings is similar to that of double-row tapered roller bearings, but it can withstand greater radial loads and has a slightly lower limit speed, which is mainly used for heavy machinery.

use

Tapered roller bearings are mainly used to bear radial and axial combined loads. The bearing capacity depends on the raceway Angle of the outer ring, the greater the Angle, the stronger the bearing capacity. This type of bearing belongs to the separation type and is divided into single row, double row and four row tapered roller bearings according to the number of rows of rolling elements. The clearance of the single-row tapered roller bearing needs to be adjusted by the user during installation; The clearance of double-row and four-row tapered roller bearings has been set according to user requirements at the factory, without user adjustment.

Tapered roller bearings are widely used in automobile, rolling mill, mining, metallurgy, plastic machinery and other industries.

Install

The installation steps of four row tapered roller bearings are as follows:

1. The inner ring of the four-row tapered roller bearing and the roller neck are generally matched with a gap, and the bearing is first loaded into the bearing box during installation, and then the bearing box is loaded into the journal.

2. Four-row tapered roller bearing outer ring and bearing box holes adopt dynamic fit, first load the outer ring into the bearing box. When leaving the factory, the outer ring, the inner ring and the inner and outer spacer are marked with character symbols, and the bearing box must be installed in accordance with the arrangement order of character symbols, and can not be replaced arbitrarily to prevent the bearing clearance change.

3. After all parts are loaded into the bearing box, the inner ring and the inner spacer ring, the outer ring and the outer spacer ring are axially tight.

4. Measure the width of the gap between the outer ring end face and the bearing box cover plate to determine the thickness of the corresponding sealing gasket.

argument

The basic dimensions of tapered roller bearings of Hunan Wa Fangdian Bearing Manufacturing Co., Ltd. are listed in the size data table:

single row tapered roller bearing: inner diameter size range 20mm ~ 1270mm; Outer diameter size range 40mm ~ 1465mm; Width range 15mm ~ 240mm

double row tapered roller bearing: inner diameter size range 38mm ~ 1560mm; Outer diameter size range 70mm ~ 1800mm; Width range 50mm ~ 460mm

four row tapered roller bearing: inner diameter size range 130mm ~ 1600mm; Outer diameter size range 200mm ~ 2000mm; Width range 150mm ~ 1150mm

The metric tapered roller bearings of Hunan Wa Fangdian Bearing Manufacturing Co., Ltd. provide ordinary tolerances, and also provide P6X, P6, P5, P4, P2 tolerance products, all in line with GB307.1.

The single-row tapered roller bearing of Hunan Wfangdian Bearing Manufacturing Co., Ltd. has a clearance only after installation, and can be determined after adjustment by another bearing positioned in the opposite direction.

Tapered roller bearings generally use steel plate pressed basket cages, and for larger bearings, solid pillar cages are used.

Allowable error equivalent dynamic load

P = Fr [KN] When Fa/Fr ≤ e

P = 0.4Fr + YFa [KN] when Fa/Fr > e

Equivalent static load

single row tapered roller bearing: P0 = 0.5Fr + Y0Fa [KN], if P0 < Fr, P0 = Fr

Double and quadruple row tapered roller bearings: P = 0Fr + Y1Fa [KN] when Fa/Fr ≤ e; P = 0.67Fr + Y2Fa [KN] when Fa/Fr > e

Suffix definition

A: Internal structure changes

B: Increased contact Angle

X: International standard for overall dimensions

CD: double outer ring with oil hole or oil groove

TD: double inner ring with taper hole

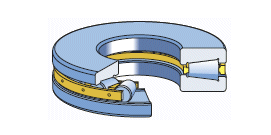

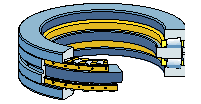

Thrust ball bearing

Thrust ball bearings are designed to withstand axial loads and remain stable at high speeds. It consists of a gasket ferrule with a ball rolling channel. According to the different shape of the ring, the thrust ball bearing is divided into flat base pad type and aligning spherical seat pad type.

Make up

Thrust ball bearings are mainly composed of the following components:

race

shaft ring

Steel ball cage assembly

The shaft is matched with the shaft ring, and the shell is matched with the seat ring.

species

Thrust ball bearings are divided into two categories according to the direction of load bearing:

unidirectional thrust ball bearing: can only withstand unidirectional axial load.

two-way thrust ball bearing: can bear two-way axial load. Wherein, the shaft ring matches the shaft. The mounting surface of the seat ring is spherical, with aligning performance, which can reduce the influence of installation error.

Thrust ball bearings can not withstand radial load, and its limit speed is low.

peculiarity

Tapered roller thrust bearing

The thrust tapered roller bearing is a type of bearing capable of forming a very compact axial configuration, able to withstand heavy axial loads, and has good impact resistance and rigidity.

Performance characteristics

The thrust tapered roller bearings produced by Hunan Wa Fangdian Bearing Manufacturing Co., Ltd. are suitable for screw fixed bearing configuration of rolling mill. These bearings have a logarithmic contact profile for optimal stress distribution inside the bearing, helping to extend bearing life.

structure

The rolling body in the thrust tapered roller bearing is a tapered roller, and the rolling busbar and the raceway busbar of the washer converge at a certain point on the bearing axis line, so as to realize pure rolling on the rolling surface, and its limit speed is higher than that of the thrust cylindrical roller bearing. Due to the small production of such bearings, the common models on the market are mostly non-standard dimensions, and the series and varieties of standard dimensions are produced less, so there is no national standard for the dimensions of such bearings.

Design and installation

The thrust tapered roller bearing with cage has a separate design so that the two washers as well as the roller and cage assembly can be easily installed independently. Full roller screw fixed bearings are held together by special positioning components for easy operation, and the washers are provided with threaded holes for lifting bolts. The following is the specific introduction:

One way thrust tapered roller bearing

Small unidirectional thrust tapered roller bearings are mainly used in the steering knuckle bearing configuration of commercial vehicles. This bearing has a full roller design and is secured by a thin steel sheet cover. Most bearings are fitted with wear-resistant, oil-resistant nitrile butadiene rubber (NBR) friction seals and are maintenance-free for lifetime lubrication with multi-purpose grease. There are many kinds of bearings, the difference is mainly in the design of bearing box seat ring and bearing cover.

The production methods of one-way bearing gaskets with larger sizes are different; Some washers are the same size as the shaft and bearing box seat ring, while others are designed differently.

With a washer of the same size as the shaft and bearing box seat ring, with a tapered raceway and a locating guard. Bearings of this design are usually used in situations where they are subjected to extremely high axial loads, such as drilling equipment turntables or crane hooks. This type of bearing has a cage and is positioned by two washers.

Other designs of bearing shaft washers have tapered raceways and positioning guards, while the bearing box seat ring is a flat design. As a result, bearings of this design are able to accept a slight eccentricity of the shaft relative to the bearing box hole without adversely affecting bearing performance. In addition to a few full roller sizes, such bearings are usually equipped with a cage concentric with the roller.

Bidirectional tapered roller thrust bearing

This type of bearing is mainly used in rolling mills with multi-row cylindrical roller bearings. Bearings with flat shaft washers are preferred because they can withstand the slight eccentricity of the shaft with respect to the bearing box hole and the slight variation in radial internal clearance used by radial bearings. A spacer sleeve is arranged between the two bearing box seat rings, the size of the spacer sleeve allows the roller bearing box cover screw to be completely tightened, and the bearing does not require special springs for adjustment.

The bidirectional tapered roller thrust bearing with tapered shaft washer usually has higher axial load bearing capacity than the bearing with flat shaft seat ring, and can position the shaft radial to a certain extent. If the load bearing capacity of such bearings is insufficient considering the required service life, double row tapered roller bearings designed with a large contact Angle can be used, see "Double row tapered roller bearings".

Because bidirectional thrust tapered roller bearings are usually installed in a loose fit on the roll journal and roll bearing box, most bearings have one or two positioning slots for the shaft seat. This makes it possible to use a key embedded in the positioning slot or other similar method to prevent the shaft seat ring from turning on the shaft.

Screw fixed bearing - tapered roller thrust bearing

This type of thrust tapered roller bearing must be able to withstand extreme axial loads and allow for angular displacement of the threaded shaft with respect to the support. Therefore, such bearings are usually full roller type, with large diameter and extra long rollers. In order to withstand the alignment deviation of the roll bearing box without adversely affecting the bearing performance, the bearing has a spherical seat. The seat ring can be a shaft seat ring or a bearing box seat ring.

The necessary alignment offset occurs in bearings with a spherical shaft seat on top of the roller set between the spherical shaft seat and the corresponding concave spherical threaded shaft or pressure baffle. Hunan Wa Fangdian Bearing Manufacturing Co., Ltd. also provides the above pressure baffle.

If the bearing box seat ring is a spherical design, the alignment deviation is borne by the roller set between the bearing box seat ring and the pressure baffle. The pressure baffle for this bearing is usually provided with the bearing.

Hunan Wa Fangdian Bearing Manufacturing Co., Ltd. produces various designs of screw fixed bearings; These bearings are customized to meet the specific requirements of specific applications.

Thrust cylindrical roller bearing

Thrust cylindrical roller bearings are often combined into high-stiffness bearing configurations that can easily withstand heavy loads and vibration loads.

intro

This kind of bearing can bear a large axial load in a single direction, but can not bear radial load, and does not have automatic aligning ability. The thrust cylindrical roller bearing can be divided into thrust cylindrical roller and cage assembly, shaft ring and seat ring.

The 811 series and 812 series thrust cylindrical roller bearings are composed of thrust cylindrical roller and cage assembly, shaft ring and seat ring, of which the most important parts are thrust cylindrical roller and cage assembly.

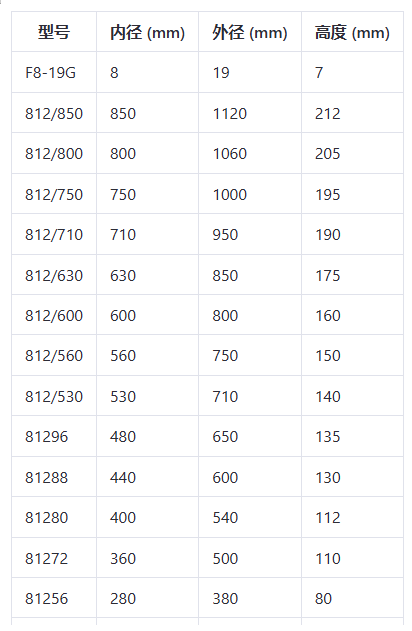

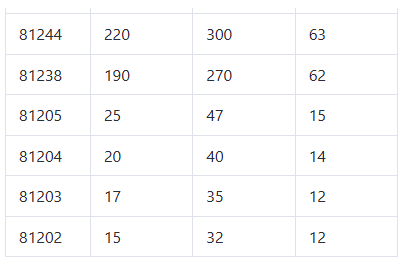

Bearing type and specification

The following are some thrust cylindrical roller bearing models and their specifications:

cage

The following types of cages can be used for thrust cylindrical roller bearings:

Moulded glass fiber reinforced polyamide 66 cage (identified as: TVPB, TVPB1)

Machined light metal cage (identification: LPB)

Machined brass cage (marked MB, MPB)

Model number

The following are some thrust cylindrical roller bearing models provided by Hunan Wa Fangdian Bearing Manufacturing Co., LTD. : 81716

82716

81117

81217

81118

81718

81720

81120

81220

89320

81722

81222

81724

81124

81224

81226

81130

81730

81230

81836

81140 / YA

89448

81192

812/500

872/530

812/560

817/600

872/670

871/710

891/800

871/850

972/900

Thrust aligning roller bearing

Thrust self-aligning roller bearings are similar to self-aligning roller bearings in that the raceway surface of the seat ring is a spherical surface centered on the point consistent with the bearing center axis. The bearing roller of this type is spherical, so it has automatic self-aligning function and is not very sensitive to the coaxiality and shaft deflection.

Product characteristics

Compared with other thrust bearings, the axial load capacity of this type of bearing is very large, and it can also withstand a certain radial load while bearing the axial load, but the radial load shall not exceed 55% of the axial load.

As long as the loads P and P0 do not exceed 0.05C0 and the shaft ring rotates, the bearing allows the aligning angles listed in the table below.

Small values are suitable for larger bearings, and as the load increases, the allowable aligning Angle will decrease.

It is usually lubricated with oil when used.

The thrust tapered roller bearing can only bear one-way axial load and limit the one-way axial displacement of the bearing, so it can be used as one-way axial positioning. Compared with the thrust cylindrical roller bearing, the bearing capacity is large, the relative sliding is small, but the limit speed is low.

Product classification

symmetrical thrust aligning roller bearing

asymmetric thrust aligning roller bearing

Size range

Inner diameter range: 60mm ~ 1120mm

Outer diameter range: 130mm to 1460mm

Height and size range: 39mm ~ 354mm

cage

The cage generally adopts brass solid frame and stamping frame. When the brass solid cage is used, the rear cage code is not marked, and in other cases, the corresponding rear code is marked.

Minimum axial load

The minimum axial load required for the operation of thrust aligning roller bearings,

FaminFamin (take the following two formulas to calculate the larger value)

Famin=C0a/1000Famin?=C0a?/1000

Famin=1.8Fr+1.33(C0a/2000)2Famin =1.8Fr+1.33(C0a/2000)2

Among them:

FaminFamin: Minimum axial load required (kN)

nn: rotational speed

C0aC0a: Basic static load rating (kN)

FrFr: Radial load (kN)

Equivalent dynamic load

P=Fa+1.2FrP=Fa +1.2Fr

Equivalent static load

P0=Fa+2.7FrP0 =Fa+2.7Fr

use

This type of bearing is mainly used in:

Oil drilling rig

iron and steel making machinery

hydro generator

vertical motor

propeller shafts for ships

Tower Crane

Extruder, etc

Bearing performance characteristics description

Aligning roller bearing installation fit - the outer ring and the housing hole should not use interference fit, the inner ring and the journal should not be too tight. If the interference fit is used in this kind of bearing, the contact Angle of the bearing is easy to change, resulting in uneven distribution of bearing load and high temperature. Therefore, the installation of the inner and outer rings of such bearings with the journal and the housing hole should generally be based on the thumb of both hands to gently push the bearing into the journal and the housing hole.